Sanitary Specified Dispense System

定量供給裝置、液體定量吐出裝置

Sanitary Specified Dispense System | 液體定量吐出裝置

Dispense for beverages and foods | 適用於飲料、食品、藥劑等,需要高衛生環境條件的液體定量吐出裝置

The dispense system designed for beverages and foods that we propose is a system with sanitary specification and that can perform fixed-quantity dispense at high speed regardless of the viscosity of attribution of an object, either liquid or solid. In addition, when the dispense system is installed on the production line, the dispense status is monitored, and an alert, alarm is issued in the event of an abnormal situation.It is ideal for enhancing the "flavor / taste" of beverage / food and to express it more accurately than ever before.

Techno Alpha製的定量吐出裝置,適合飲料,藥品,食品用等排出/填裝且符合衛生標準,是一種無論液體或固體,不管粘度如何,都可以以較高的速度進行固定數量排出的裝置。另外,在生產線上該裝置的異常監控,對物體有無吐出、吐出設定值上下限、吐出狀態等進行監控,並在出現異常時發出警報。因為可非常精確地控制吐出需求量,非常適合需要增強飲料或食品風味的生產環境。

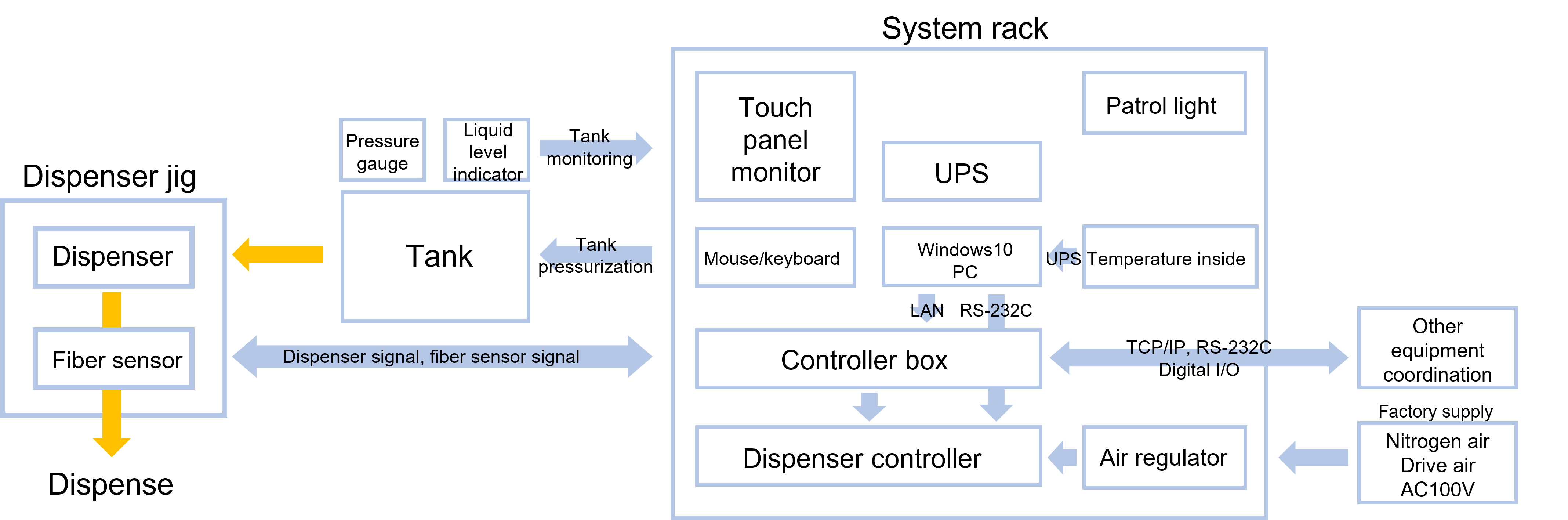

Basic Configuration Of Dispense System / System Diagram | 吐出裝置基本配置/系統圖

The system configuration of the dispense system is consisting of three main units. ;1. Dispenser part, 2. Tank part, and 3. System rack part. The configuration of each unit is shown as a diagram as below.For further details on each unit, please refer to the product / configuration.

吐出裝置的系統構成大致分為三個單元。 1. 分配器部分,2. 水箱部分,3. 系統機架部分。每個部件的配置如圖所示。有關每個部件的詳細信息,請參閱產品/構成。

Figure 1 Dispense System standard model diagram |

吐出裝置標準系統圖(點擊放大)

Features | 特點

High-performance dispenser | 高性能分配器作為標准設備

- Dispense of solid and highly viscous liquids

- Micro quantity dispense

- Low variability, High reproducibility

- controlling the temperature of the target liquid

- 支援吐出固體和高黏度液體

- 可以處理微量吐出

- 實現降低排出量不均和高再現性

- 通過管理目標液體的溫度,讓溫度不會改變黏著性或不損害物體的風味。

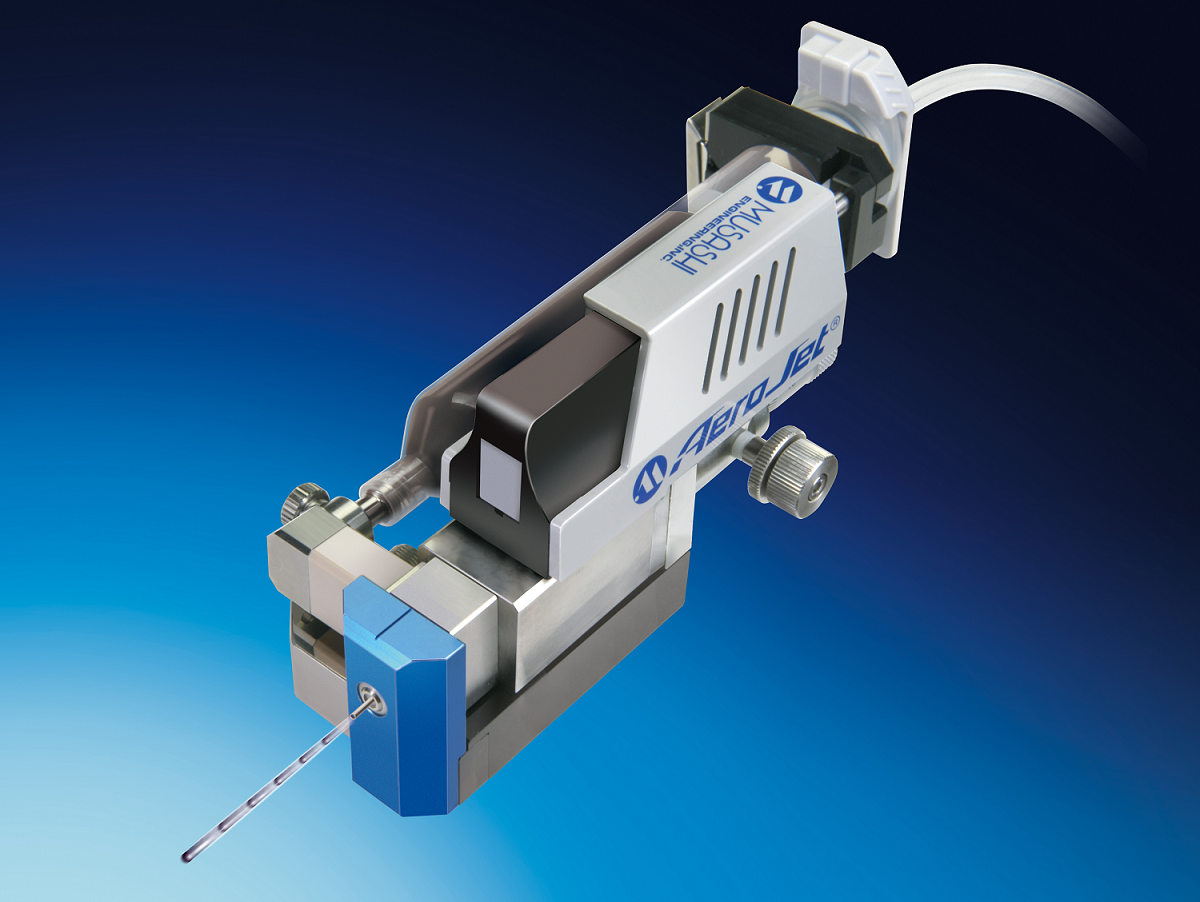

Figure 2 Dispenser | 分配裝置

PC and PLC control can be selected, and remote monitoring is also

supported.

可選擇PC和PLC控制,也支持遠程監控。

- Monitor a series of flows

Detection of dispense target

⇒ Dispense

⇒ Judgment of dispense presence / quantitative evaluation

⇒ Counting of OK / NG number

⇒ Management of production number, etc. - Monitor & record all dispenses

100% monitoring of normal dispense / 100% recording of dispense pass and fail / Output a rejection signal when dispense is abnormal

- 監控流量

檢測吐出目標

⇒ 吐出

⇒ 吐出有無判斷/定量評價

⇒ OK / NG 數量的計數

⇒ 生產數量的管理等。 - 監控和記錄所有排放吐出

正常吐出全面監控/吐出是否正常全面記錄/吐出異常時發出異常信號

Interlock mechanism | 隨付互鎖機制

- The user can set the conditions for continuing, stopping, and excluding of production.

- 生產繼續、停止和排除條件可由用戶設置。

CIP(Cleaning in Place)、automatic cleaning | 自動清洗對應

- The user can set the conditions for continuing, stopping, and excluding of production.

- 生產繼續、停止和排除條件可由用戶設置。

Operator-oriented maintenance design | 以操作員視角所設計的維護保修

- General-purpose products are used for each sensor and device, and they can be easily replaced.

- Supports remote monitoring and software updates, and alerts can be set on smartphones.

- 每個傳感器和設備都使用通用產品,可以輕鬆更換。

- 支持遠程監控和軟件更新,可在智慧手機上設置警報。

Specification | 規格

The specifications and videos of typical dispensers are shown as below.

下面是基本分配器的規格以及相關動畫。

| Series 系列 |

Aero JET |

|---|---|

| Dispensing 吐出方式 |

Jet 噴射方式 |

| Function 主要機能 |

Non-contact coating 非接触注入 |

| Dispense mode 吐出模式 |

LINE/MAN, LINE/SET, DOT/MAN, DOT/SET |

| Liquid feed pressure setting 液送壓力設定 |

0.000~0.500[MPa] |

| Dispense time setting range 吐出時間設定範圍 |

LINE Mode(模式時) ON TIME:2.00~99.99[msec] OFF TIME:1.70~99.99[msec] |

| Dispense frequency setting range 吐出回數設定範圍 |

1~9,999times(LINE mode/模式時) |

| Supply air pressure 供給空氣壓力 |

0.450[MPa]over(dry air/乾燥空氣) |

| Usage environment 使用環境 |

Temperature/温度:15~35[℃] Humidity/濕度:25~75[%](no condensation) Elevation/標高:2,000[m]below indoor use only/室内専用 |

| Storage environment 保存環境 |

Temperature/温度:1~60[℃] Humidity/濕度:5~80[%](no condensation/但是沒有冷凝) |

| Mass 重量 |

About 520[g] ※It depends on the piping specifications. ※取決於配管規格 |

| Wet contact material 接液材質 |

Stainless steel / Fluor rubber 不銹鋼/氟橡膠 |

| Applicable nozzle 適用噴嘴 |

Dedicated nozzle 專用噴嘴 |

| Applicable valve seat 適用閥座 |

Dedicated valve seat 專用閥座 |

| Proven material 採用實績原料 |

Fragrances, chocolates, additives, alcohol, etc. 香料・巧克力・添加物・酒精等 |

Applications | 應用

Here are some typical application examples.

If you have any needs about discharge other than the followings, please contact us.

以下是一些典型的應用範例。

如果您有以下以外的吐出需求,歡迎與我們聯繫。

Micro / fixed quantity dispense of flavors for beverage production lines

Challenge: Adding flavors to conventional beverage fillers does not work

⇒Use the dispense system to dispense the appropriate amount of the target liquid to each can.

飲料生產線,香精、香料微量定量吐出

課題:以往向飲料灌裝機添加香精和香料是行不通的

⇒ 使用吐出裝置將適量的目標液體注入到每個罐中。

Micro and fixed quantity dispense of fragrances for food production lines

Challenge: Want to increase the product lineup by slightly arranging current jam products

⇒Dispense system is to be newly installed in the post-process of food production lines in

order to dispense a combination of each flavor material and fruit liquid.

食品生產線,香精、香料微量定量吐出

課題:通過稍微安排及調整,改變現有的果醬產品來增加產品陣容。

⇒目前,在產品生產的後工序中安裝了吐出裝置,通過將各種風味材料和果液結合後進行吐出。

Design production with chocolate and fresh cream for confectionery production line

Challenge: Want to draw multiple characters with chocolate

⇒Draw different characters by using a discharge device equipped with XYZ function

零食生產線,巧克力和鮮奶油的設計生產

課題:利用巧克力畫出多個不同的角色

⇒使用配備XYZ功能的吐出裝置繪製不同的角色

Dosing of liquids for pharmaceutical production lines

Challenge:Want to perform high-speed, high-precision micro-dispensing

⇒Achieves a micro dispense of several nanoliter by using a dispense system

製藥生產線液體計量

課題:我想進行高速、高精度的微量吐出

⇒ 通過使用吐出裝置,可實現數 nl 的微小吐出。

Contact Us

Please enter the input form below for asking quote, P.O. or any questions.