Conductive/Semi-conductive inks for Printed Electronics

Silver nano ink/Zinc oxide nano ink/Transparent conductive ink

用於印刷電子、導電/半導電性墨水

銀納米墨水/氧化鋅納米墨水/透明導電墨水

Silver nano ink/Zinc oxide nano ink/Aluminum Zinc Oxide nano ink/Transparent conductive ink

GenesInk is a leading company in the manufacture of state-of-the-art nanomaterials and nano inks for printed flexible electronics.Their Silver nano ink / Zinc Oxide nano ink / Aluminum Zinc Oxide nano ink/ Silver nanowire ink for Transparent conductive provide excellent performance in the development of thin flexible devices and fields where high conductivity and high energy efficiency are required.

法國的GenesInk是製造用於印刷軟性電子產品的墨水,是先進納米材料,納米分散體及納米油墨的領導者。GenesInk的導電墨水[銀納米墨水(Ag納米墨水)],半導體墨水[氧化鋅油墨(ZnO墨水)]和透明導電墨水[銀納米線墨水]在開發高導電性及高效能的軟性電子設備,提供出色的性能。

Silver nano ink

Ideal for applications such as flexible devices, consumer electronics and IoT.

軟性電子設備和IoT物聯網等應用的理想選擇,銀納米粒子墨水。

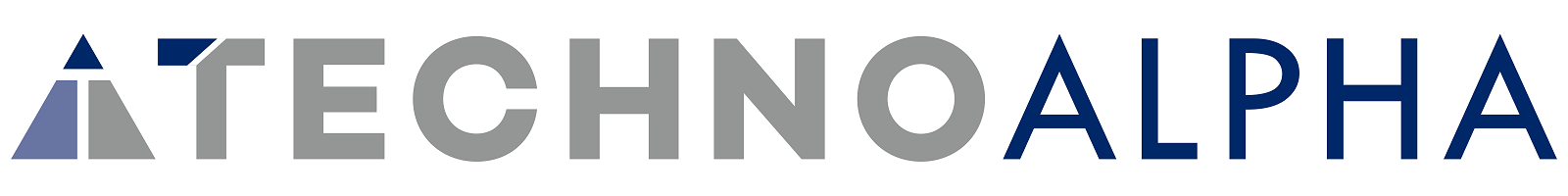

Superiority of Silver nano ink | 銀納米粒子墨水特性

Low resistivity with silver nano:2.5 µΩ.cm

5 to 8 time more conductive than flakes

↓

Lower material consumption: up to 10 times less printed material

↓

Raw material savings

低電阻率:2.5 µΩ.cm

(Smart Screen R15 min @ 200°C)

導電性是傳統薄片型銀膏的8倍左右

↓

對比傳統銀膏,粒子型的納米油墨僅使用約1/8的量,即可製造出具有相同導電性的產品

↓

實現成本降低

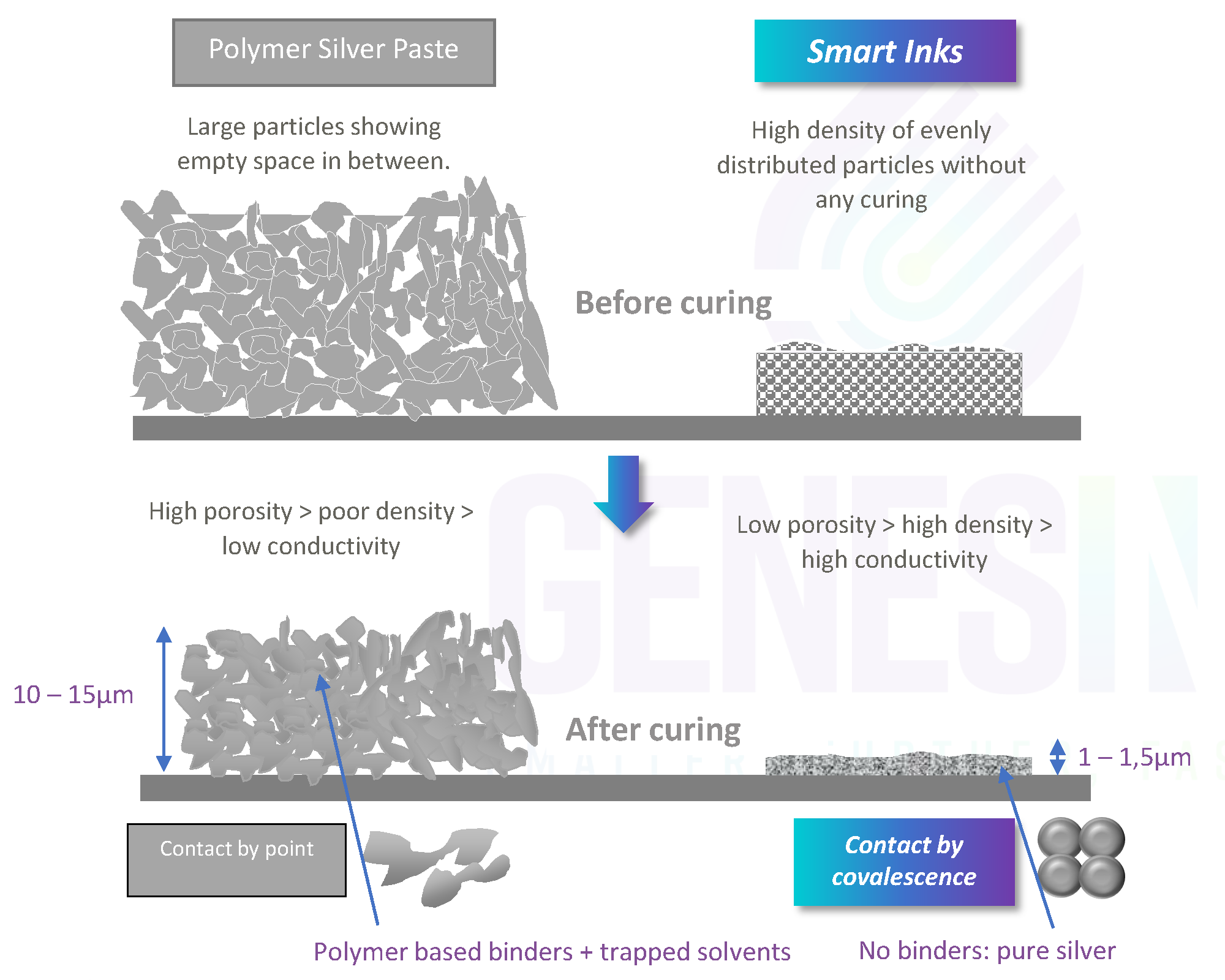

Flexibility due to thickness,

adhesion and nanostructure

↓

Offers a 2-3 mm bending radius

↓

Easier to integrate in a final system.

Enables new device design.

納米尺寸(數十nm),高附著力,

薄厚度,高抗彎曲性

↓

彎曲半徑2mm至3mm

↓

設備小型化的理想選擇

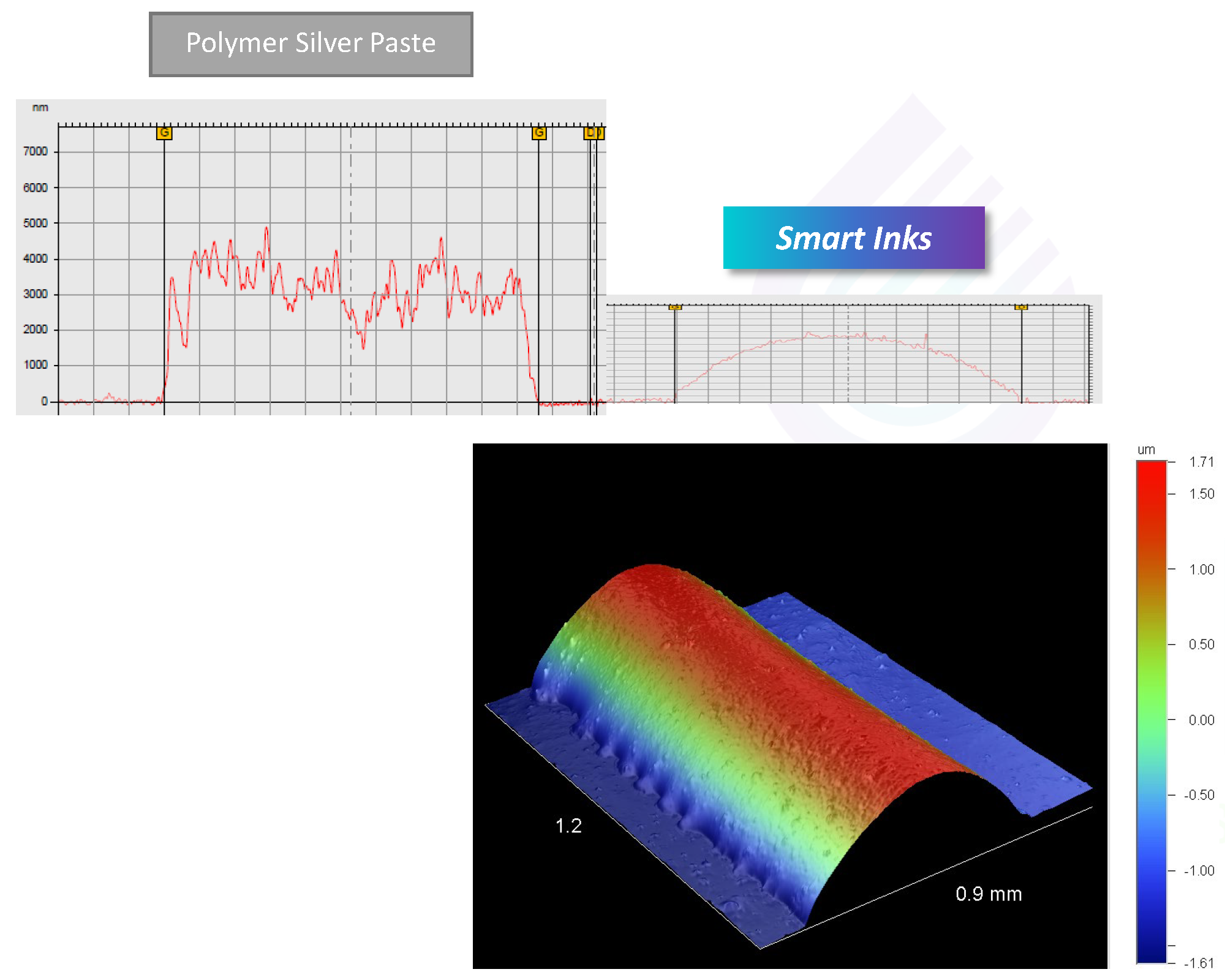

Thin printing (1.5-2.5µm)

Very smooth surface

↓

Use less ink

Allow 1 layer of dielectric (Vs. 2 for flakes)

No touch feeling

Mirror aspect (aesthetic)

↓

Raw material savings

薄型印刷(1.5-2.5µm)

表面非常光滑

↓

減少墨水用量

允許1層介電層(相對於薄片2層)

觸感良好

鏡面(美觀)

↓

節省原材料

Ability to make 50µm width lines

↓

Enable denser bus connection (number of line in a limited space)

↓

Enable smaller user devices

能夠製作50µm寬度的線

↓

更密集的線數排列

(在有限空間中增加線數)

↓

用戶可製作更小的裝置

High Specific Surface Area of nano particle improve energy transfer

↓

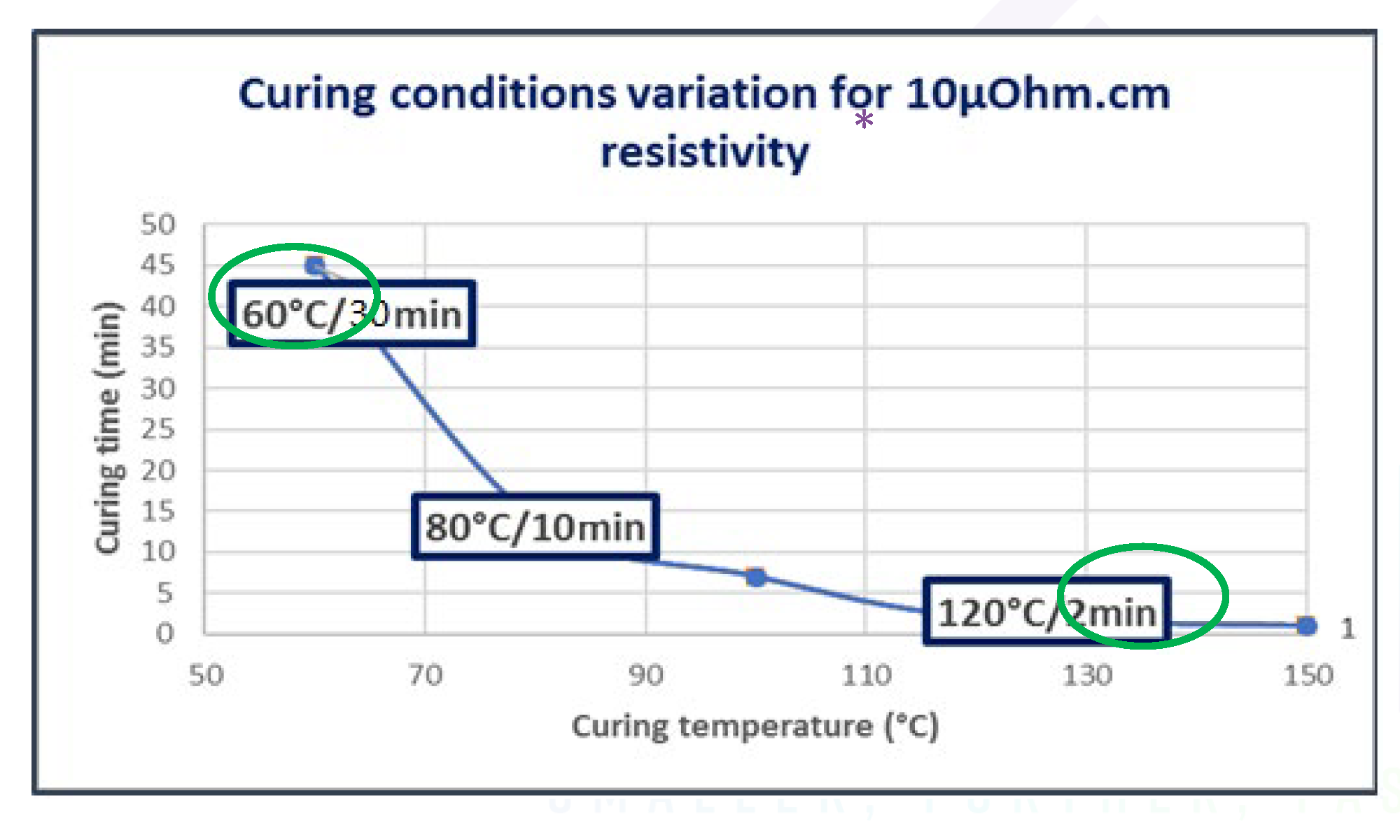

low curing temperature (≤ 80°C)

Short curing time (≤ 5min)

↓

Improve productivity and cost reduction

納米粒子的高特異性表面積可改善能量轉移

↓

固化溫度低(≤80°C)

固化時間短(≤5min)

↓

提高生產率並降低成本

Features | 特色

- High conductivity due to high bonding between silver nanoparticles

- Excellent printability (wetting, resolution, adhesion, etc.) with their unique ink formulation technology

- High bending resistance and low surface roughness

- Low temperature baking, quick baking process

- Total cost merit

- Compatible with various baking processes (tunnel furnace, vacuum oven, IR, light baking)

- Compatible with various flexible boards (PET, PEN, Kapton, etc.)

- Non-carcinogenic, non-mutagenic, non-reproductive toxic ink

- Ready to use inks with no thinner needed

- Storage stability for about 6 months

- 由銀納米粒子之間的高鍵合而獲得的高導電性。

- 通過獨特的油墨混合技術實現出色的可印刷性(潤濕性,分辨率,附著力等)。

- 銀納米粒子優異的結合性和多孔性,實現了高抗彎曲性和低表面粗糙度。

- 低溫烘烤,快速烘烤製程

- 少量使用即可達到相同效果,成本優勢。

- 兼容多種燒成工藝(隧道爐,真空烘箱,遠紅外線,光燒成)。

- 兼容各種軟性板(PET,PEN,Kapton等)。

- 非致癌,非突變原,非生殖毒性油墨。

- 無需稀釋劑即可使用的墨水

- 儲存穩定性,約6個月。

Zinc Oxide nano ink / Aluminum Zinc Oxide nano ink

High-efficiency, long-life organic photovoltaics (OPV) cells.High-brightness and Flexible for OLED lighting.

氧化鋅(ZnO)和鋁摻雜的 氧化鋅(AZO)納米粒子墨水,可實現高效能,長壽命的有機太陽能板和高亮度軟性的有機發光二極體(有機EL、OLED)。

Features | 特色

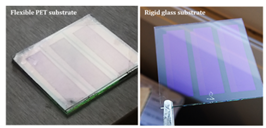

- Applicability to various flexible substrates such as PET

- Low temperature firing ink for 80 °C to 120 °C

- Low light activation duration as devices are activates in less than 30 seconds

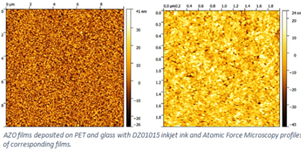

- Illuminance with excellent uniformity by suppressing surface roughness

- Improvement of photoelectric conversion efficiency of organic solar cells (PCE> 10%)

- Achieves a brightness value of 10 times or more in organic EL compared to conventional PEI

- High tech formulation with very good storage stability

- Functions as a protection layer, prevents deterioration during oxidation and UV irradiation

- High production capacity at competitive cost

- 適用於各種軟性基材,如PET

- 80°C至120°C的低溫燒結油墨

- 對光反應所需時間較低,可在30秒以內反應。

- 通過抑制表面粗糙度實現均勻度極佳的照度

- 提高有機太陽能板的光電轉換效率(PCE> 10%)

- 使用在OLED當中,其亮度值是傳統PEI的10倍以上。

- 高科技配方,具有很好的儲存穩定性

- 並起到保護層的作用,防止氧化和紫外線照射時的變質。

- 以具有競爭力的成本提高生產能力

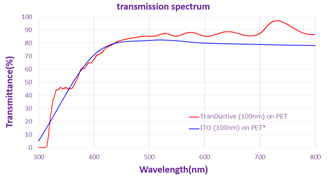

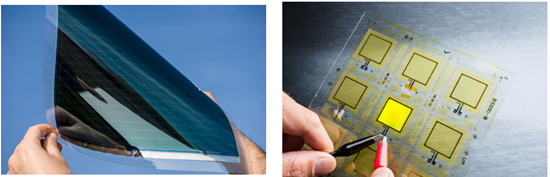

Transparent conductive ink

Silver nanowire ink that can replace current ITO film and ITO coating in organic EL and organic solar cells.

Tranductive®一種銀納米線油墨,非常適合OLED和有機太陽能板的ETL(電子運送層),以及透明電極,且可以代替現有的ITO塗層。

Features | 特色

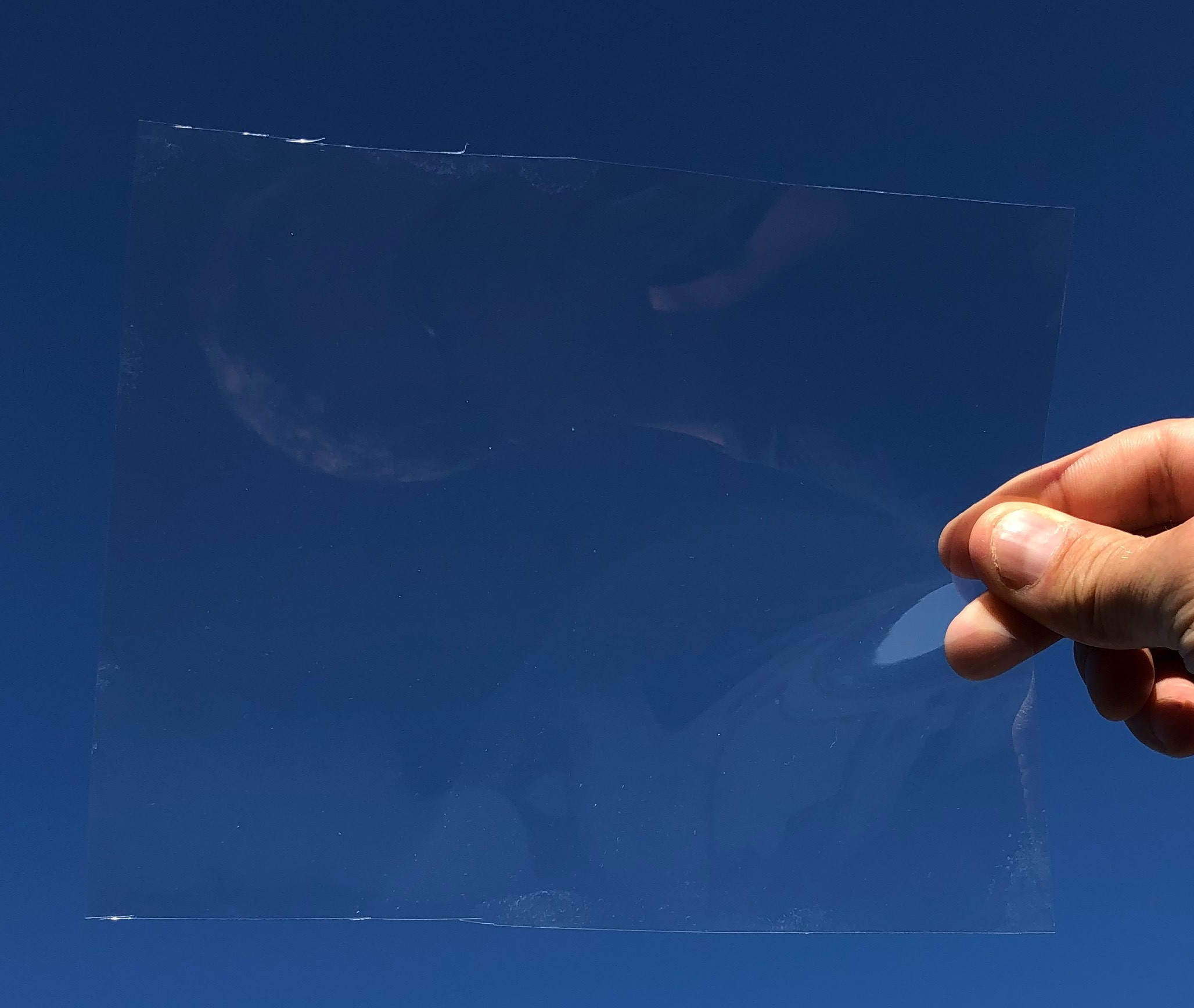

- Mass production is possible by roll-to-roll method

- Tunable conductivity from 10 to 300 Ohm/sq

- Homogeneous conductivity over the printed surface

- Good transparency above 90%

- Manufactured with existing, low-cost equipment No sputtering equipment required, low temperature baking (e.g.: 90 ° C-120 ° C, 90 seconds, hot plate)

- Allow manufacturing of very thin films for ultra-flexible devices

- Very Low roughness between 5 and 10nm

- Reduces deterioration over time with their unique high blending technology

- 適用於roll to roll生產方式,可進行大量生產

- 可調節表面電阻率從10到300 Ohm / sq

- 印刷表面的均勻導電性

- 90%以上的透明度

- 使用現有的設備即可生產製造,低成本

- 無需濺射設備,低溫燒結(例如90°C-120°C,90秒,加熱板)

- 可製造出薄型且軟性的設備電子

- 針對超柔性設備,5至10nm的極低粗糙度

- 通過獨特的高複合技術,減少隨著時間推移的變質情況

Aplication

- Application of smart devices Silver nano ink could be used for wiring patterns on substrates such as PET, PEN, and paper, making it a thin and light device.

- NFC packaging Conventional NFC (Near Field Communication) smart packaging uses aluminum material and etching method, but by using silver nano ink, it is possible to easily generate an antenna in the printing process.

- Touch sensor It can be used for metal mesh for touch sensors.

- 更輕薄的設備 可以使用銀納米墨水在PET,PEN和紙之類的基材上生成佈線圖案,從而實現設備輕量化。

- NFC 傳統的NFC(近場通信)使用鋁材料和蝕刻方法,但是使用銀納米墨水,可以輕鬆的印刷天線。

- 觸摸感測器 可用於感測器的網狀或迴圈結構。

Organic EL / Organic solar cells | 有機太陽能板和高亮度軟性有機發光二極體

The organic EL (OLED) market is a fast-growing area where printed electronics products are used. GenesInk is effective for ETL (electron transport layer) and TCF (transparent conductive film) with high specifications (conductivity, transmittance, etc.) and process improvement (low sintering temperature, printability, etc.).

有機EL(OLED)市場的快速成長,也是印刷電子產品可以發揮的領域。GenesInk墨水對ETL(電子傳輸層)和TCF(透明導電膜)具有高規格(導電性,透射率等),在製程的改進(低燒結溫度,可印刷性等)也有顯著的成效。

Contact Us

Please enter the input form below for asking quote, P.O. or any questions.