Products

Topological Materials

Introduction of Topological materials

TopoLogic Inc., the University of Tokyo's first startup company, is working on Topological Materials

that, due to the uniqueness of their band structure, exhibit two macro effects: the "anomalous

Nernst effect (ANE)" and the "anomalous Hall effect (AHE)."

These

enable devices with new

characteristics.

With the anomalous Nernst effect, it is possible to realize a thin

and

simple thermal flow

sensor. This opens the door to applications such as biometric sensors capable of detecting

thermal

comfort, abnormal detection in batteries or semiconductors, predictive monitoring of

manufacturing

equipment failures, heat leakage detection, insulation detection, and thermoelectric devices.

On the other hand, the anomalous Hall effect can achieve

ultra-fast

magnetic memory. This has

promising applications for embedded first-level cache memory, low-power memory for IoT devices,

and

non-volatile logic devices.

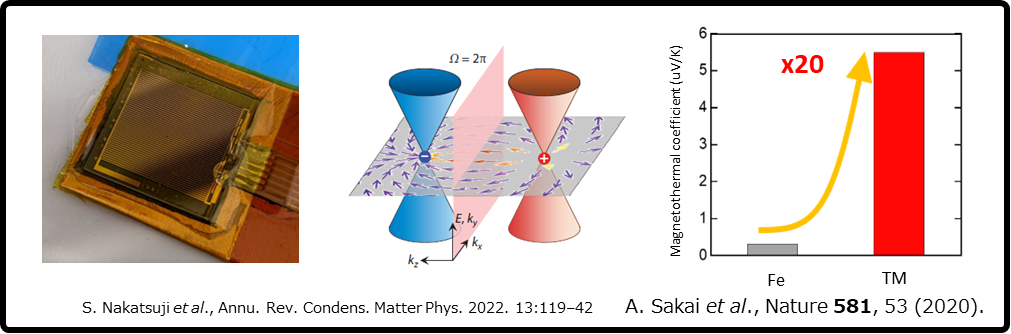

Tehno Alpha will promote advocacy and projectization of the company's topological

materials in

collaboration with TopoLogic Inc. The business model consists of selling or licensing the

company's

intellectual property.

Fig. Business model scheme

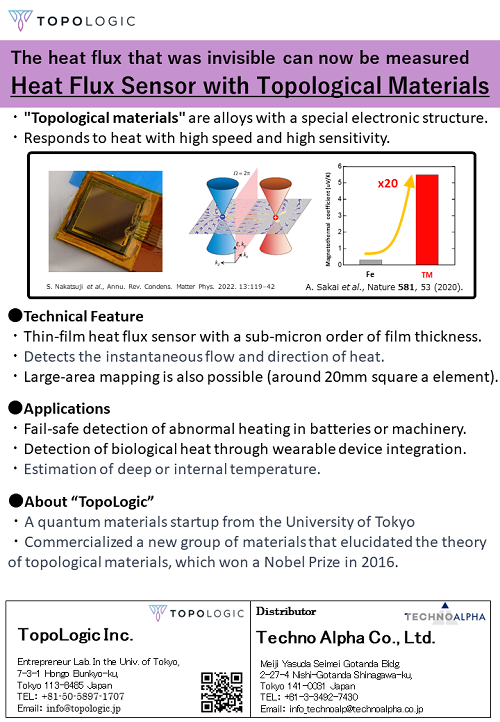

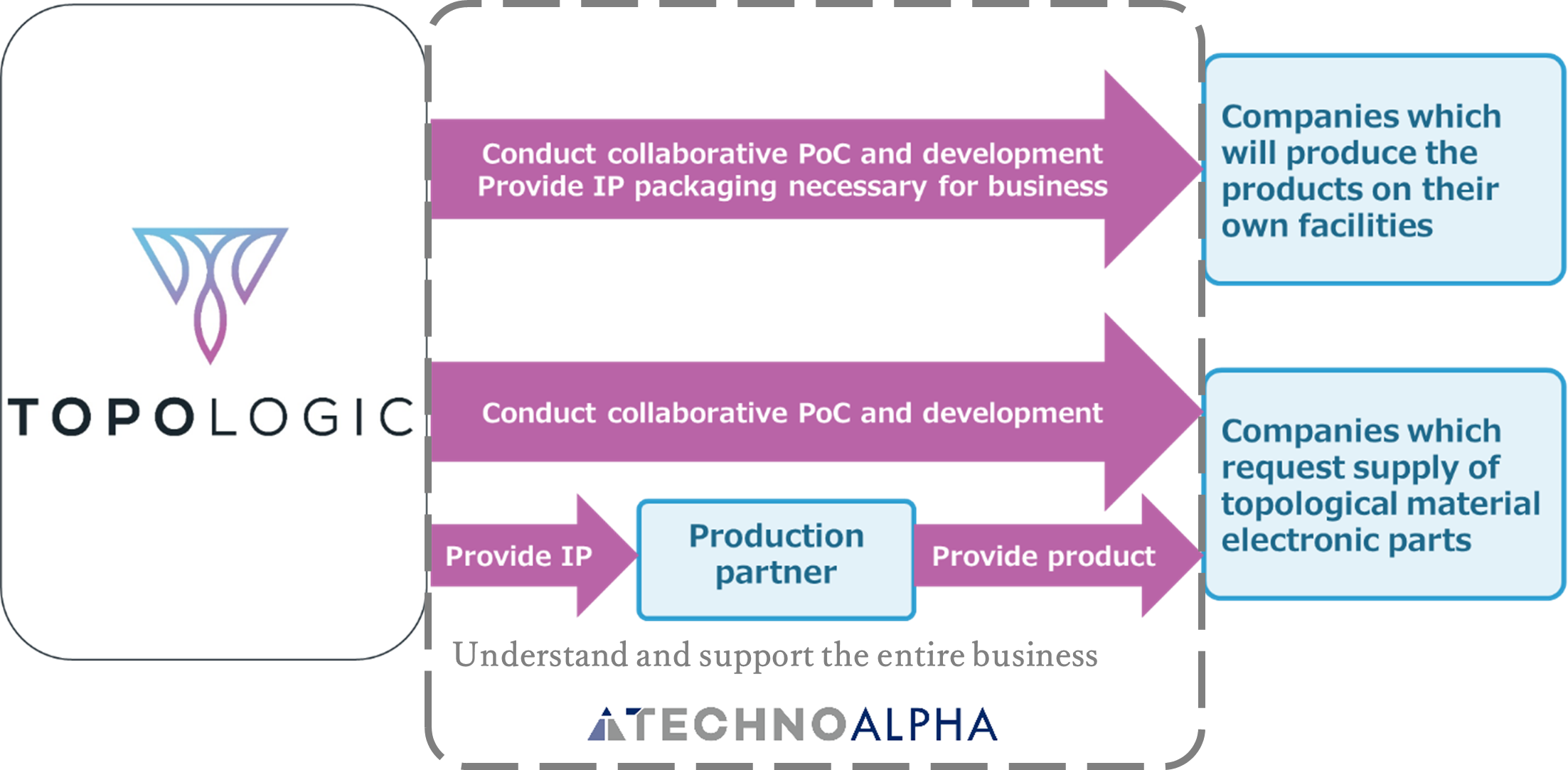

What is “topological materials?

Topological materials are substances with unprecedented electron structures that were awarded the

Nobel Prize in Physics in 2016. In the past, similar discoveries have been made in the realm of

semiconductors. Topological materials derive their name from their topological features

(topology)

within the electron bands, which include singular points such as Weyl points and Dirac points.

These

singular points give rise to highly potent virtual magnetic fields (microscopic magnetic fields)

and

induce unique electron flow within the material. As a result, they exhibit various

electromagnetic

properties unlike those found in other materials.

The main macroscopic effects stemming from the band structure of topological materials are

the

anomalous Nernst effect and the anomalous Hall effect. These effects are a consequence of the

influence of the virtual magnetic field in topological materials and are particularly

characteristic

of them. These effects are not observed in existing materials, allowing for the realization of

devices and electronic components with entirely novel structures.

One of these distinctive macroscopic effects, the anomalous Nernst effect, is a type of

thermoelectric effect where a voltage is generated in response to a temperature gradient within

a

material. A similar thermoelectric effect known as the Seebeck effect is commonly recognized,

but

while the Seebeck effect generates a voltage potential in the same direction as the temperature

gradient, the anomalous Nernst effect generates a voltage potential perpendicular to the

temperature

gradient. Conventional thermoelectric materials faced challenges such as complex structures,

limited

thinness, and high costs due to the voltage differential aligning with the temperature gradient.

In

contrast, utilizing the anomalous Nernst effect in thermoelectric devices allows for the design

of

highly versatile thermoelectric devices, as the direction of the temperature gradient and

voltage

potential differ.

What is TopoLogic Inc.?

TopoLogic Inc. was founded in July 2021 as a quantum materials startup originating from the

research

group of Professor Tomo Tsujii in the Department of Physics at the University of Tokyo. The

company

aims to implement and bring to society new devices based on "topological materials" researched

and

developed by the group.

TopoLogic focuses on the lateral thermoelectric conversion effect and spintronics based on

novel orders, striving to achieve the development of devices that were previously challenging to

realize.

Fig. Awards / Selections records

Device & Applications

Heat Flux Sensor “TL-Sensing™

Additionally, this sensor can be manufactured through traditional processes like sputtering, allowing for cost-effective production and easy integration into existing manufacturing lines. It offers economic advantages compared to conventional models (ranging from tens of thousands to a few hundred thousand yen). Furthermore, it can be deposited on a variety of substrates, including silicon, plastic, and film, without being restricted by substrate type.

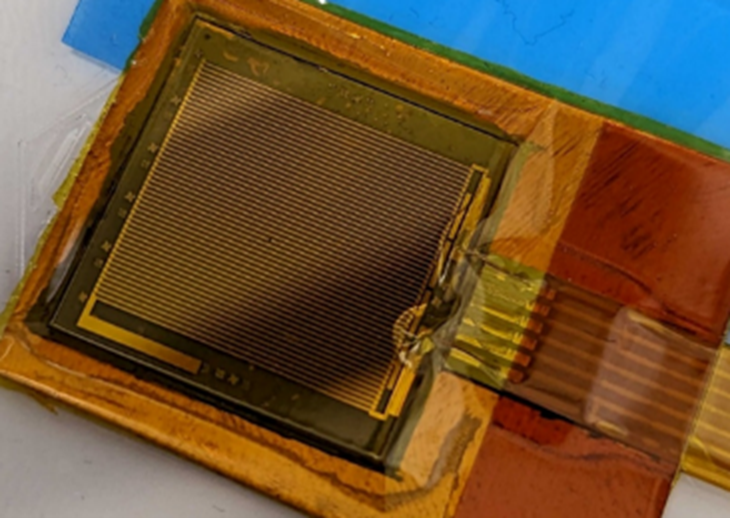

| Dimensions | Substrate - 20×20×0.5mm

Element Circuit - Meander structure |

Demonstrates thinner profile compared to existing heat flux sensors |

|---|---|---|

| Thermoelectric Performance | 0.2μV/W/m2 | Exhibits comparable thermoelectric performance to existing heat flux sensors |

| Time Constant | 0.01seconds | Shows a 100x faster response compared to existing heat flux sensors |

| Materials (Sputtering) |

MgO Substrate: thickness 0.5mm

Topological Material: thickness 100nm Surface Protection: Kapton Tape |

Features a simple structure compared to existing sensors, providing excellent reliability and manufacturability. |

| This device is an easy-to-use demonstration sensor available for collaborative testing and evaluation. During collaborative development, we will tailor the sensor's specifications, such as area, shape, thickness, and substrate material, to meet your company's specific needs. | ||

For Temporary Use

As the sensor provides analog output, when evaluating parameters like sensitivity, we recommend utilizing your existing data logger, measurement power source, oscilloscope, or similar equipment to assess and verify the sensor's performance.

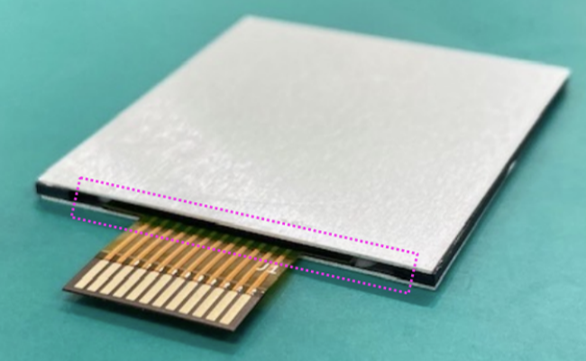

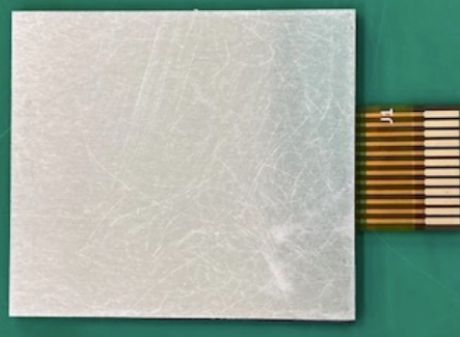

| Dimensions | Substrate - 20×20×0.5mm

Element Circuit - Meander structure Package: 36×32×1.6mm |

Demonstrates thinner profile compared to existing heat flux sensors |

|---|---|---|

| Thermoelectric Performance | 0.2μV/W/m2 | Exhibits comparable thermoelectric performance to existing heat flux sensors |

| Time Constant | 0.5 seconds | Shows faster response compared to existing heat flux sensors |

| Sensor Element (Sputtering) |

MgO Substrate: thickness 0.5mm

Topological Material: thickness 200nm |

Features a very simple structure compared to existing sensors, providing excellent reliability and manufacturability |

| Sensor Configuration | Aluminum packag

Heat bonding using silicone resin and TIM material for thermal connection |

Packaged to protect the sensor element |

| Price | Available for lending starting from 100,000 yen per 2 weeks | Long-term lending and evaluation support are also available |

| If you're interested in borrowing our sensors, please don't hesitate to contact us for more details on availability, pricing, and any specific requirements you might have. Our goal is to provide you with an opportunity to experience and evaluate the capabilities of our sensors effectively. | ||

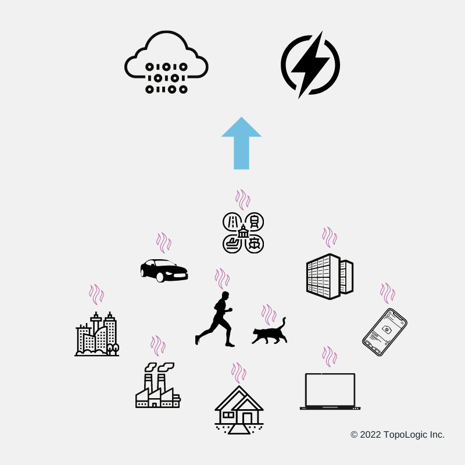

Applications of Heat Flux Detection

For instance, they can be used to visualize heat generation in manufacturing processes, detect abnormal heat generation, and predict and monitor failures based on heat. In the context of wearable devices, they can monitor heat dissipation (absorption) from the human or animal body, allowing for estimation of health conditions and comfort levels. These sensors can also be integrated into automotive and IoT devices, enabling diverse heat-related monitoring.

Additionally, by introducing substances that react with specific chemicals on the sensor's surface to generate reaction heat absorption, it's possible to detect various substances like gases or antigens. These sensors have the potential to detect heat absorption from various activities in the world, making them versatile tools for activity monitoring.

Chemical Sensors and Gas Sensors

By introducing a catalytic layer as a functional film onto the surface of the heat flux sensor

element,

it becomes possible to enhance reactions with specific substances, enabling the detection of

heat

flows

resulting from these reactions. Leveraging this principle, for instance, by employing a platinum

catalytic layer to promote the reaction with hydrogen, the sensor can detect the presence of

hydrogen

based on the resulting heat flow. Using the sensitivity of this type of heat flux sensor, it's

also

conceivable to detect hydrogen concentrations as low as a few parts per million (ppm). This

capability

allows for the detection of even minute hydrogen leaks from pipes or tanks in hydrogen plants

and

fuel-cell vehicles.

Moreover, by selecting an appropriate functional film, the application can extend beyond

hydrogen

detection. It becomes possible to detect various types of gases, such as ammonia or hydrocarbon

gases.

This versatility in gas detection is achievable by tailoring the catalytic layer to suit the

specific

gas of interest.

Optical Sensors

When light shines on a heat flux sensor (or an optical absorption film placed on its surface), the energy of the light is converted into heat. By detecting this heat with the heat flux sensor, the device can be functioned as a light-receiving element, essentially acting as an optical sensor. Leveraging the high-speed response of TL-Sensor™ heat flux sensors, light reception can be detected within an order of 0.01 seconds. This capability enables a more responsive feedback system compared to conventional light-receiving element-based systems.

High-speed Memory

At present, it may not be possible to provide specific application examples, but it holds the potential to realize promising memory technology in the future.

Pamphlet

Contact Us

Please enter the input form below for asking quote, P.O. or any questions.